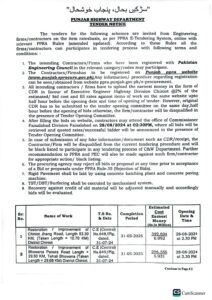

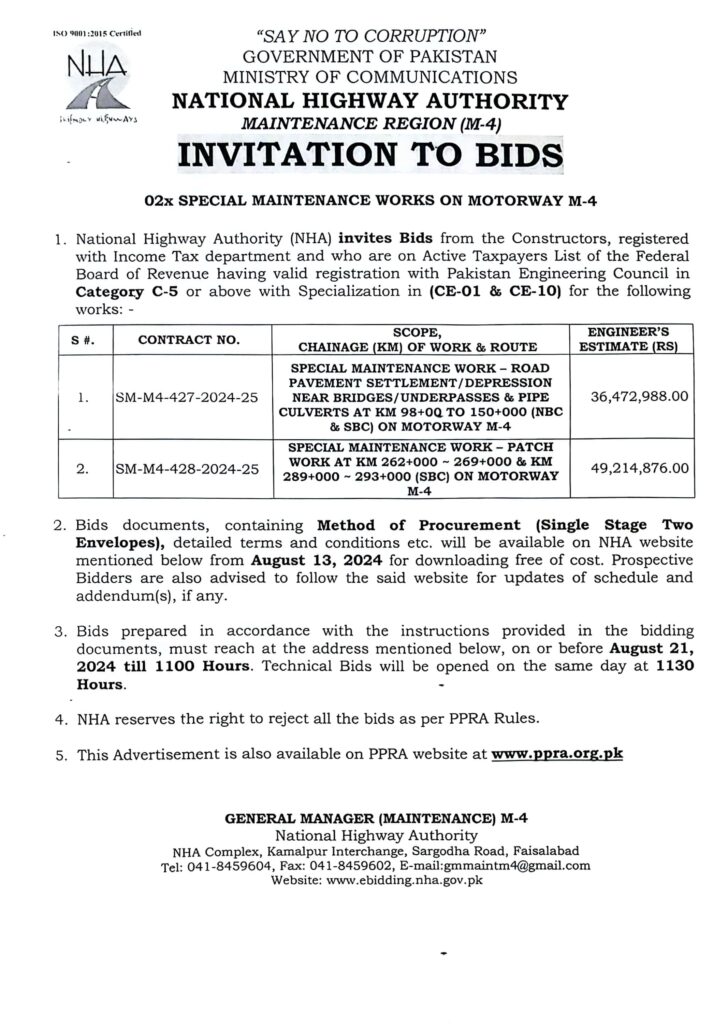

Special Maintenance Work:

SM-M4-427-2024-25 Special Maintenance Work Road Pavement Settlement Depression Near Bridges Underpass & Pipe Culverts at Km 98+00 to 150+000 NBC & SBC on Motorway M-4. E/Cost 36.42 Million, SM-M4-428-2024-25 Special Maintenance Work Patch Work at Km 262+000 to 269+000 & Km 289+000 to 293+000 on Motorway M-4 E/Cost 49.214 Million

General Manager (Maintenance) M-4 NHA Faisalabad.

Certainly! The special maintenance work you’re referring to addresses road pavement issues, specifically settlement depressions near bridges, underpasses, and pipe culverts along a section of Motorway M-4. Here’s a detailed breakdown of the type of work involved:

Project Overview

Project Name: Special Maintenance Work Road Pavement Settlement Depression Near Bridges, Underpasses, & Pipe Culverts

Location: Motorway M-4, Km 98+00 to 150+000

Estimated Cost: 36.42 Million

Type: Special Maintenance

Objectives

- Address Pavement Settlement: Repair and stabilize areas where the road surface has settled or sunken, particularly around critical infrastructure like bridges, underpasses, and pipe culverts.

- Ensure Road Safety: Improve the overall safety and driveability of the motorway by eliminating hazardous depressions.

- Extend Pavement Life: Prevent further deterioration and extend the service life of the road surface.

Scope of Work

- Inspection and Assessment:

- Visual Inspection: Conduct a thorough visual inspection of the affected areas to identify and map out all settlement depressions and other pavement issues.

- Geotechnical Investigation: Perform soil testing and subsurface investigations to determine the underlying causes of the settlement.

- Preparation:

- Traffic Management: Implement traffic control measures to ensure safety during construction. This may include lane closures, detours, and signage.

- Site Preparation: Remove the damaged pavement and any debris. Prepare the site for repair work by ensuring proper drainage and stabilization.

- Repair Work:

- Excavation: Excavate the affected areas to reach the foundation layers that need attention. This may involve digging around the bridges, underpasses, and pipe culverts.

- Subgrade Stabilization: Stabilize the subgrade with suitable materials such as geotextiles, soil stabilizers, or replacement fill to address any weaknesses.

- Culvert and Bridge Adjustments: Ensure that the pipe culverts and bridge foundations are properly supported. Reinforce or repair any structural components if necessary.

- Pavement Replacement: Reconstruct the pavement in the affected areas. This involves laying new asphalt or concrete layers and ensuring proper compaction and leveling.

- Quality Control:

- Testing: Conduct quality control tests on the new pavement to ensure it meets all engineering and safety standards. This may include tests for compaction, thickness, and material properties.

- Inspection: Perform a final inspection to verify that all repairs have been completed to the required standards.

- Finalization:

- Cleanup: Remove all construction equipment and debris from the site. Restore any areas affected by the construction work.

- Reopening: Gradually reopen lanes to traffic while monitoring the repaired sections for any signs of further issues.

Key Considerations

- Environmental Impact: Minimize environmental disruption and ensure proper disposal of any waste materials.

- Durability: Use high-quality materials and techniques to ensure the longevity of the repairs.

- Cost Management: Monitor expenditures closely to stay within the estimated cost of 36.42 Million.

Timeline

The project timeline will depend on the extent of the repairs needed and weather conditions. A detailed schedule should be developed to outline all phases of work and key milestones.

This type of maintenance work is crucial for maintaining the structural integrity and safety of the motorway, especially in areas subject to high traffic loads and complex infrastructure.